Mold Building

Molds Made to the Highest Standards: Our Own

Global Leaders In Designing, Engineering, And Manufacturing High-Precision Injection Molds

Building molds to the most stringent standards takes unmatched insight and extensive real-world experience. As an industry-leading molder, we’re in the unique position to deliver quality, performance, and longevity. We leverage our experience and our vertically-integrated tooling company, Accuchrome, along with our deep global network of best-in-class tooling partners to assist our customers design and build tools that meet each program’s unique specifications, budget, and lead times.

We understand that the heart of a successful program is the tooling, and we take our responsibility seriously. From designing and engineering molds, to building and running them, we take ownership at every step to ensure your success.

Experience, partnership, and end-to-end accountability are what sets us apart.

Experts In High-Precision Mold Manufacturing

Our Vertically-Integrated Mold Building Company

Global Tooling Partnerships, Forged Over Decades

Leveraging Our Global Machine Supply Base To Match The Right Mold With The Perfect Machine For The Application

Industry-Leading Mold Life Asset Management

We build, run, and maintain your molds as if they were our own.

Optimal Molding Solutions, The Heart Of A Successful Program

It’s more than just building molds: we are creating the foundation for successful programs that will produce life-saving devices and mission-critical products for the world’s leading companies. Optimal tool design and quality of construction are the cornerstones of successful injection molding programs.

Every mold is unique and has specific requirements surrounding part geometries, critical tolerances, raw materials, and more. Our team’s unmatched experience, combined with the latest DFM tools in the industry, allows us to analyze and specify every aspect of your tools. From design, steel types, and runner systems, to gate configurations, cooling systems, and internal actions, we reliably deliver the highest-quality parts and solutions for your application and budget.

Whether we are building the mold in-house, or with one of our global suppliers, we know exactly how to find the perfect solution for your needs.

Let our team of experts be yours.

Our Specialties

From pilot molding and prototyping to world-leading spinning cube capability, our integrated team of experts gives you the highest-quality parts in the shortest possible time.

Our business and reputation is built on creating parts with extremely tight tolerances and consistency. We’re the go-to supplier for accuracy and solutions to the most complex challenges.

We use advanced molding, precise temperature control, and optimized processes to minimize defects and variations — ideal for industries where even small deviations can impact functionality.

High cavitation molding enhances precision injection molding by enabling the production of multiple identical parts simultaneously, increasing efficiency and reducing cycle times — a Technimark specialty.

We push the limits on cavitation to enable breakthrough success for our customers.

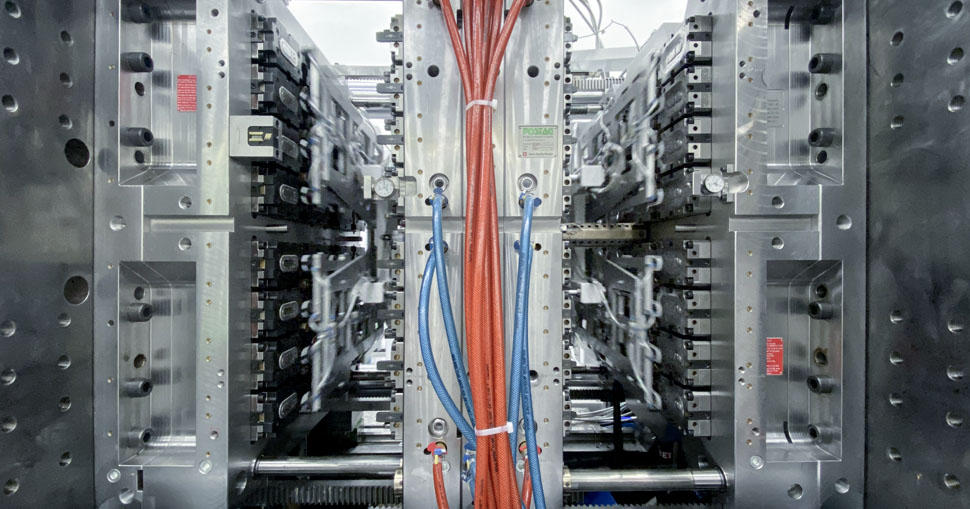

Stack molds optimize material flow and cooling across layers, ensuring consistent quality. Our stack molds double or triple production efficiency by molding multiple layers of parts in a single cycle, without increasing the machine’s footprint.

Ideal for high-volume production, stack molds are cost-efficient and improve output. Whether you’re in healthcare, consumer packaging, or industrial, you’ll have the peace of mind knowing it will work.

As experts in spinning cubes, we maximize efficiency by enabling simultaneous operations like injection, cooling, and ejection on different cube faces. When it comes to complex, high-precision projects, we use this technology to reduce your cycle times and improve productivity.

Working with Technimark gives you seamless integration of complex designs with in-mold transfer technology, such as overmolding or decorating, in a single production cycle. It improves efficiency, reduces handling, and ensures precise alignment, making it ideal for your high-quality, multi-component products.

Multi-shot molding enables the production of multi-material or multi-color parts in a single cycle by injecting different materials sequentially or simultaneously.

This process ensures precise bonding between materials, reduces assembly steps, and enhances design flexibility — perfect for creating complex, high-quality parts.

Modular molding uses interchangeable mold components to allow quick reconfiguration for different part designs or features. As an experienced mold builder, we control each part to ensure optimization and efficiency.

This flexibility reduces downtime, lowers cost, and enhances efficiency, especially for short production runs or diverse product lines.

Our Innovation Center is second to none and has everything your project needs to make it successful. Our in-house prototyping lets us quickly design, test, and refine parts, reducing lead times and development costs while giving you something tangible to feel and feed back on.

Prototyping gives us greater control over the process, accelerates innovation, and provides faster feedback loops — ideal for when you need rapid iteration with unmatched precision.

Before your product is created, we place the label in the mold fusing it directly with the plastic creating a high-quality and aesthetic finished product that’s resistant to scratching and fading and stands out on the shelf.