Automation

Precision Automation For Efficiency, Consistency, And Quality

Leading the way in Advanced Automation

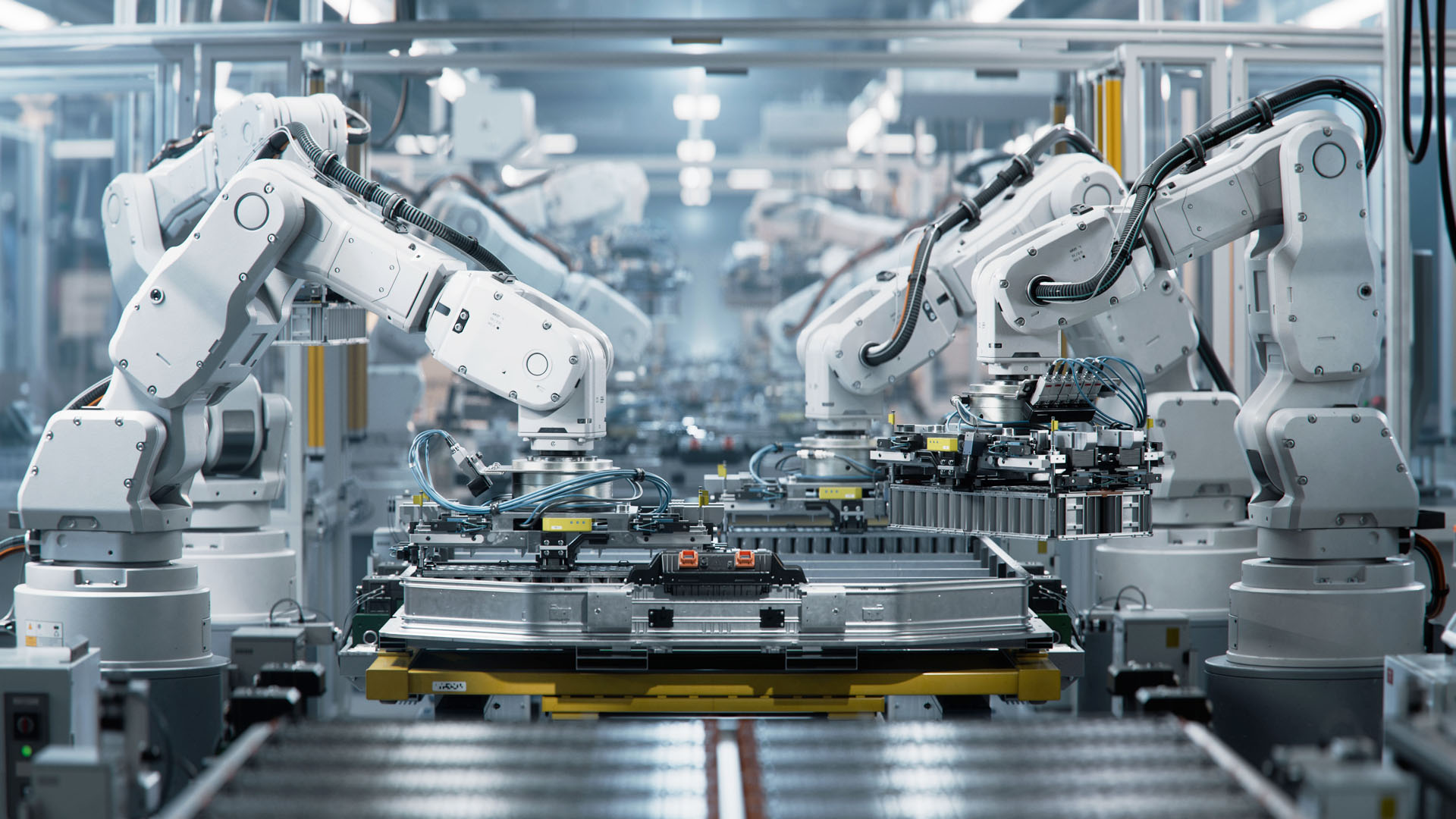

We design and build innovative, custom automation systems that orient, place, insert, assemble, and inspect multiple components for low, medium, and high-volume applications.

You can trust our bespoke automated assembly systems that deliver precision, efficiency, and exceptional quality.

How We Lead The Way

In-House Capabilities, Outstanding Partners

We can develop and build your automation in house or collaborate with our proven global automation partners.

We’ll select from the world’s best talent and match their skills to your project’s specific needs. Which means you get the best team — and best results — every time.

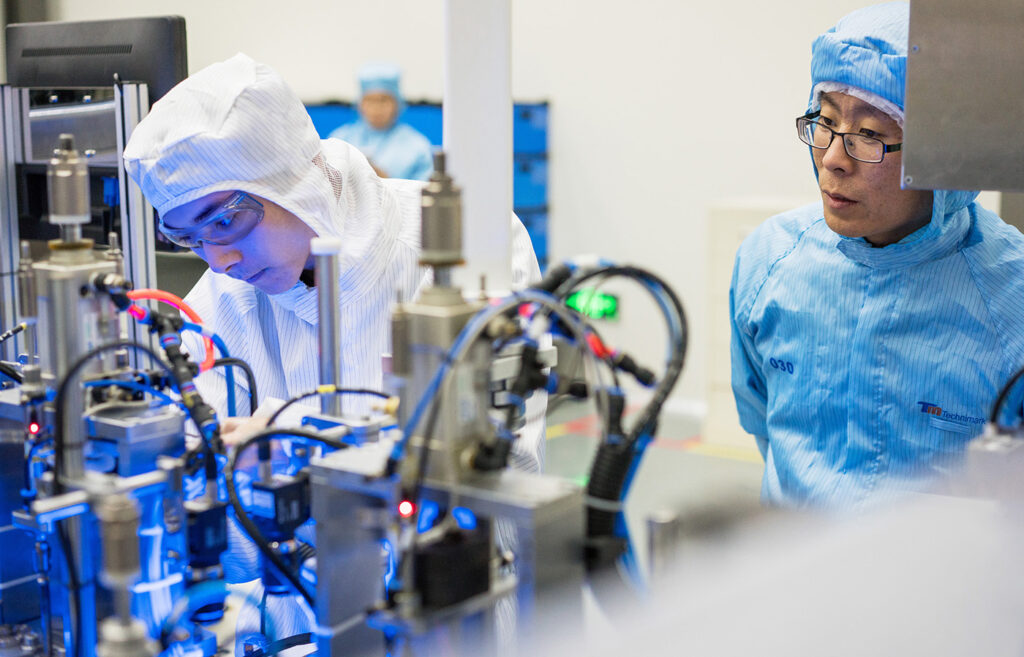

Deep Expertise

When it comes to mechanical, electrical, software, and manufacturing engineering, our team of engineers is second to none.

Bringing their unmatched expertise to bear, they deliver both fully and semi-automated cells, so you get the optimal solution.

We Own It

We take ownership of every step, from concept, development, and system build through production.

It’s this cultural commitment to taking responsibility that means the world’s most respected — and demanding — companies trust us to get it right.

The Automation Experts

We routinely design, build and globally deploy some of the most complex automated systems in our industry. At any scale, we deliver the thought leadership, innovation, and precision required to deliver custom solutions that are perfectly aligned with your specific needs.

Automation And AI: Our Path To Zero Defects

We’re harnessing the power of AI and advanced inspection technologies to create market-leading advances in quality, giving you total confidence at the highest speeds possible.

Automating the future

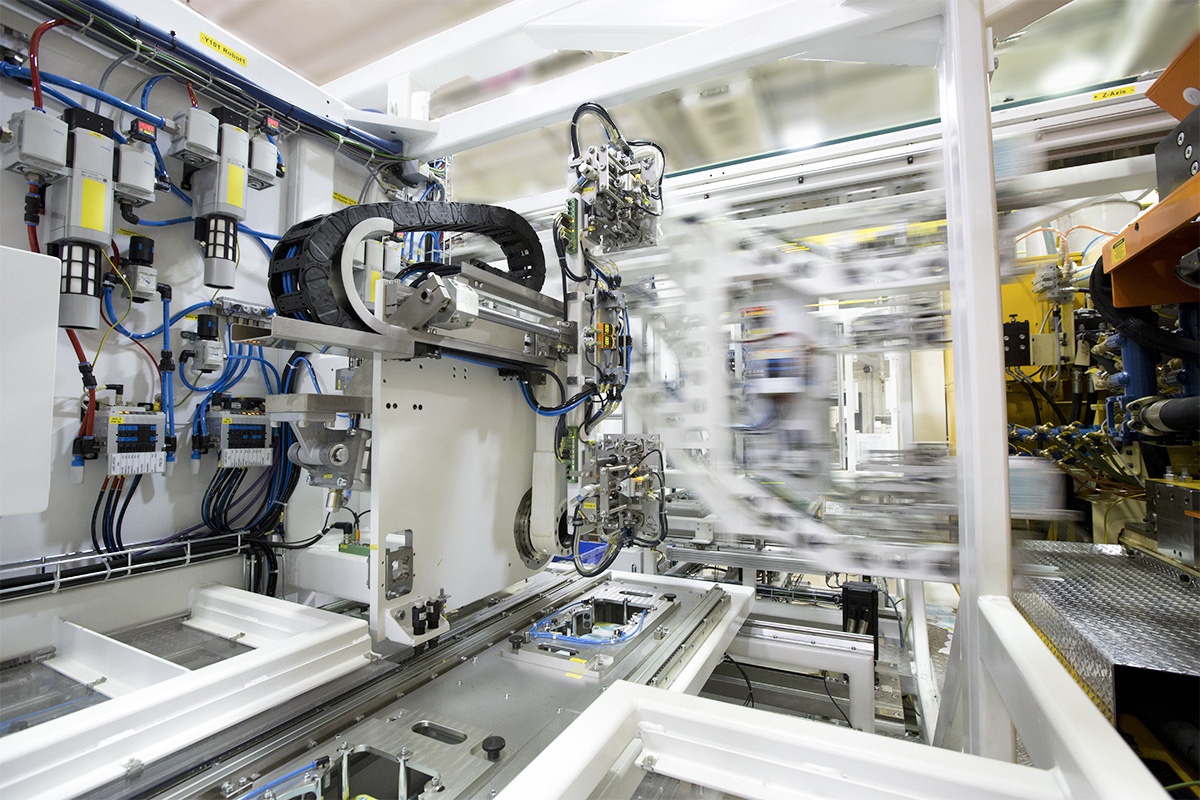

Our complex platforms enable the assembly of multiple components, post-mold forming, decoration, and inspection at speeds up to 1000 ppm.

We also offer low-volume production to perfect process and product before we scale.

- Systems for assembly of multiple components, die cutting, inspection, welding, and decoration

- Semi-manual and semi-auto equipment for low-volume production of assembly applications

- Joining methods including ultrasonic, hot plate, infrared, and radio frequency

- Hot melt and chemical dispensing

We use the latest technologies to guarantee superior quality at high speeds, including:

- Vision

- Pressure and Flow Check

- High-Potential Voltage Testing

- Weight Check

Full suite of decoration solutions to seamlessly add the final touch to your products, including:

- In-Mold Label

- PSL

- Hot Stamp

- Heat Transfer

- Silk Screen

- Digital Printing

- Metalization

- Sleeving

- Painting

Our packaging solutions include:

- Packaging equipment for cartoning, bagging, and case filling

- Six axis robotic systems (guarded and collaborative) for automatic packing

We do more than make products and components — we optimize automated systems to give our customers a competitive advantage.

This is an ongoing commitment to support and continuous improvement for the life of the product.